In leather crafting, you need to have several tools in your kit. Even a beginner’s leather crafting kit has at least five different tools needed to start in making even the most basic leather project. In case you’re a beginner and on a budget or you’re a long-time leatherworker that wants to acquire tools without spending too much, there are some leather working tools you can try making on your own.

What are some leather working tools you can make at home? By using the right tools, you can make a chisel or pricking iron using a fork. You can also make an edger using a rusted up wood chisel. A DIY edge slicker only needs a block of wood. Using huge nails and metal bolts, you can make and customize your own stamping tools.

Having the right leather working tools in your workspace is always beneficial. In this article, I’ll guide you through the different leatherworking tools you can make. I’ll also squeeze in bonus tips for other materials you can use as alternatives to some of your leather crafting tools.

Easy and Quick Do-It-Yourself Chisel

Leather chisels, also called pricking iron, are tools used to punch through the leather to make guide holes for sewing. You usually pound on them using a mallet to make the leather holes. There are one-pronged chisels or the usual six-pronged ones. The diamond-shaped tip of the chisels is perfect for bookmaking and scrapbooking, crafts that even the hole guides add to the aesthetic of the project itself.

Chisels aren’t generally expensive nor hard to find. You can buy a piece for around $6 to $12, depending on the number of prongs. A set of three or four chisels sell for around $19 to $50. The more expensive ones are actually used for a hand-press chisel machine.

If you don’t want to spend some bucks on chisels, it’s quite easy to do. All you’ll need is a fork, ideally the one with thicker prongs or teeth. You’ll also need a marker, a small saw, a hammer, a steel file, and a workbench vice to tightly hold down the fork as you work. This is optional, but if you have a metal pipe and a block of wood, keep them handy as well to make a handle for your chisel.

Starting Off with a Fork

First, you straighten out the curves of the fork using a hammer. Take a good look at your flat fork. Using a marker, draw a line across the prongs where all of their width are even. Don’t go too low though, or you might lose the prongs you’ll need for your chisel. After marking, cut off the excess prongs with a saw. Secure the fork on workbench vice, with its prongs pointing up.

Ending with a Homemade Chisel

Grab your smaller steel file and start filing on each prong. Make sure that you aim to file on the four sides of each prong to get the diamond-shaped points. Be careful with filing too much though, you don’t want to end up having uneven prongs, so don’t over do it. After filing all four prongs, test out your DIY chisel on a scrap leather to see its consistency and sharpness.

You can now start using your chisel, but if you want it to have a better grip, make a handle using a metal pipe and a chunk of wood. The metal pipe should be the same size as the handle of your chisel, so cut out excess if needed. The chunks of wood should also be the same size of the pipe. Insert it in the pipe, the tighter, the better. Grab your chisel and squeeze it in between the wood chunks all the way up to the widest part of the chisel. Your chisel has now a thicker handle.

Make Your Own Edger at Home

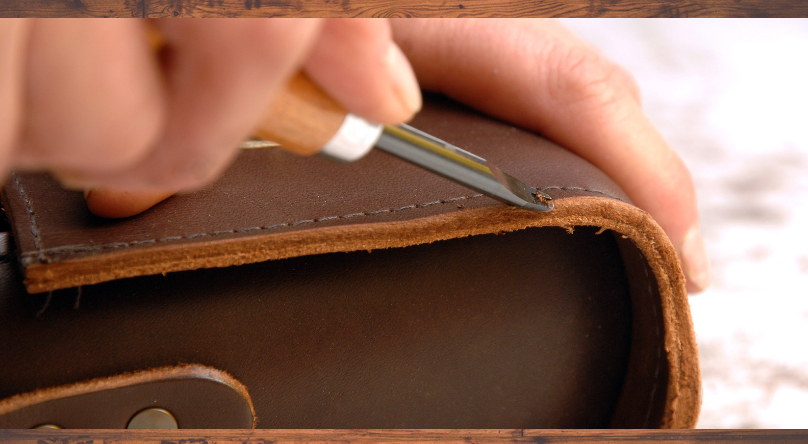

An edger is used to convenient slice or trim off leather edges. It’s also the tool used in making round corner edges. These are done on leather pieces for aesthetic purposes, as well as add comfort in handling the leather craft such as wallets and belts. Ideally, these leather crafts feel better to touch and use when they have softer and rounded edges.

Edgers are usually sold per piece or per set. It comes in different sizes, catering to the different leather thickness you may use it with. An edger may sell for $9 to around $50 per piece. A three-piece or four-piece edger set sells for around $20 to $70. In making your own edger, you’ll only need an old wood chisel or a screwdriver, bench grinder, workbench vice, marker, and a steel buffer.

Take Your Pick: Chisel or Screwdriver

Take out your blunt wood chisel or screwdriver for this project. You can make two sizes of edgers if you have a wood chisel and a screwdriver. The wood chisel is perfect for making a bigger edger and the screwdriver for a smaller edger. Take your pick on which tool you’ll rework, or what size of edger you think you’ll need most.

Start by buffing off the rusted part of your chisel or screwdriver. Once you get a nice texture on the metal part, depending on how the tip of the screwdriver looks, you can either cut it off or work with it to make the edger. Use the bench grinder to sharpen the edge of your tool. Once you’re done, place your the tool on the workbench vice

Groove for Your Edger

Grab your steel file and start making a groove in the middle of the sharpened edge of your tool. Use a slightly bigger file, if you’re working on a bigger edger. However, in case you want to be more careful, using a smaller steel file is okay. Use the buffer to polish your new edger, and test it out to check its groove size and sharpness.

How to Make a Slicker from Scratch

Another tool you can make on your own is the one that you use to burnish the edges of the leather. It’s called a slicker, usually made of wood with grooves. You rub the leather on these grooves which burns the leather fibers and burnishes the edges. Burnished edges are ideal for leather crafts like gadget cases, belts, and wallets.

Slickers usually have either a single groove or multi-grooves. A single groove slicker costs around $5 and looks like a flat wheel. A multi-groove slicker sells for around $6 to $60. For your slicker project, you’ll need a small piece of wood that is at least five inches long, a bench grinder, a workbench vice, and a marker.

Shaping the Wood

If you have an old and unused wooden stool or a cane lying around the house, you can use that to make your slicker. For an old stool, grab one of its legs and cut off around five inches long, same thing with an old wooden cane. You can make a longer one if you like. Using your bench grinder, smooth out the edges to get a rounder top, similar to how a slicker looks like.

Place the piece of wood horizontally on the workbench vice. With your marker, draw two to four groove marks on the wood, just make sure they’re not too close to each other. You should also have an ample space for holding the slicker. Start filing on the marked edges to make different sizes of grooves.

Finishing the Slicker

Once you’re done making the grooves, it’s time to run the slicker on the bench grinder once more to polish the grooves. Be careful while working on this because you don’t want to end up having the same groove sizes for your slicker. After this, polish your homemade slicker to remove splinters. Grab a piece of leather and try out your slicker.

Design Your Own Leather Stamping Tools

Leather stamping tools are one of the most important tools you need in your kit when you want to explore adding designs and texture to your leather crafts. Aside from making an impression on the leather, stamping tools are also used to define these impressions, giving them a three-dimensional effect. There are different types of stamping tools, such as a pear shader, beveler, and background stamps.

Stamping tools are sold either per piece or per set. Individual stamping tools sell for about $7 to $55 per piece. An entire set consisting either of one type with different sizes or a set of different types cost around $20 and above. To make your own leather stamping tools, you’ll need either huge steel nails and metal bolts, a bench grinder, a rotary tool and disk, and sandpaper.

Nails and Bolts

Start by filing the nails and bolts to remove rust. The nails can be used to make bevelers and pear shader stamps. It’s easier to shape the nail’s head because it’s thinner compared to a bolt’s head. In making patterned stamps, use the bigger metal bolts. Carefully grind off the head to get a smoother texture before moving on to designing and shaping.

Shaping and Designing Your Own Stamp Tools

Using your bench grinder, shape the head of the nails into a beveler or a pear shader. The sides should be smoothly rounded off, almost sloping down. For your patterned stamp, use the rotary tool and disk to make customized design impressions on your metal bolts. Finish your stamp tools by using sandpaper to grind off the rough parts. Grab a leather and try out your DIY stamping tools.

Bonus: Alternative Tools You Can Use Immediately

Now, if you don’t have some of the power tools mentioned in this article or need to use an alternative tool asap, there are some things lying around your house that you can temporarily use as substitute leather working tools. It’s all about being resourceful, really. You might even find it ridiculous, but as long as it works, then there’s no reason why you shouldn’t use them.

Probably the most common substitute tool is a nice fork to act as a chisel. No need to redo the teeth or prongs, just use them as is to make your guide holes. Another great alternative tool to make leather holes is a drill. An X-acto knife or a box cutter can also be used in roughing out the edges of your leather by rubbing the blade against the grain sides before gluing them together.

Conclusion

Being creative and resourceful are important traits in leathercrafting. Exploring your options and materials to make your own tools isn’t actually a new thing for leatherworkers. Making your own tools using ordinary materials you can find in your house or workshop is highly encouraged by leatherworkers. In case you discover alternative tools or options that can help you with your leather projects, then go ahead and do that to save you money and time.